Recycling at Tubeway Sales

Following the publication of a number of blog articles regarding Recycling and Waste plastic, it forced the Tubeway Blogger to seriously consider our own role in the discussion. As a manufacturer of Plastics products, are we doing all we could in the fight against Plastic waste and other forms of recycling; should we roll over and become guilty by association or can we grab the bull by the horns and lead by example.

We decided to do the latter so let’s explore what we found…….

The challenge: How can Tubeway Sales better improve the processes we have in place for waste management and recycling?

To start we needed to assess the type of plastic and waste we handle on a daily basis, the easiest way to consider this is breaking it down to three categories:

- the plastic we manufacture

- the plastic we handle in our role as a manufacturer and wholesaler

- that generated as a result of non-manufacturing processes i.e Office/Kitchen

1) Manufacturing waste

In its simplest form our business is as a plastic extrusion company, we make long lengths of plastic profiles used in a huge variety of settings. Previous blogs in this series have highlighted why Plastic profiles make such suitable candidates in numerous settings, the whys and wherefores are best addressed in these. Have a read of Waste Plastic Products – action by government for further information.

We thought an understanding of what we do might help the discussion, so should any of you have an interest on the details of the extrusion process an annotated diagram can be found here: https://www.tubewayextrusions.com/custom-production.html

There are two stages to the extrusion process that generated “waste” plastic.

The first is in pulling up the profiles, there is a certain amount of Production waste generated until we’re able to produce the profile in the exact dimensions required and dictated by the customer. All the plastic generated in the machine start up is re-processed in house, chipped down and re-run as recycled compound. We have several customers who make use of this for jobs where colour isn’t important or where they themselves are looking to meet certain environmental markers in sourcing a plastic product. In this scenario it’s a win:win for both us and the customer and we’re able to pass on a cost saving to them versus running the profile in virgin material.

The second stage of production waste is during the machine clean down, this is when the profile is finished and we clean down the machine, particularly the barrel of the machine for the next job. Unfortunately, this generates waste that until now we’ve been unable to recycle as the plastic slugs are too large for our regrinding machinery.

We have taken steps to try and address this in the past but the availability of said services is challenging. At the start of 2019 we engaged with a Innovate UK funded project, undertaken at the University of York they are trying to develop a new chemical recycling process for PVC which specifically aims to convert phthalate plasticisers into a REACH compliant by-product. The study is in its early stages, but we have outlined our commitment to stay involved.

Read on to learn what steps we are now taking to recycle this element of our Plastic Waste.

2) Waste we receive

Amazingly the vast proportion of the plastic and other waste we have onsite is not that which we have generated, it’s a result of the goods and materials we receive (, backing up the data in the Plastic Pollution report). Typically packing comes in one of two forms, Cardboard or Plastic.

Carboard: Most of the boxes we receive containing raw materials or products are stripped and re-used to send our own goods out in. For those that we can’t or for offcuts from our own packaging we had a contract with the local council where they collected a 500l on a weekly basis.

Plastic: This is by far the most volume generating source of waste we have onsite. Examples of this would include compound bags, Polysleeves and Shrink wrap. Whilst we can make use of some of this re-packing goods, in no way could we re-purpose all, to date this has been going to landfill.

3) Non-manufacturing waste

As with any business we also generate a fair amount of recyclable office waste, in addition to that generated from kitchen and food waste. Confidential paperwork is shredded and used within packing, non-confidential gets added to the cardboard bin collected weekly. Kitchen waste was generally placed in a bin and added to general waste.

In considering the above it was clear we needed to take steps to address our current processes, there were several things we could be doing better. We started engaging our current suppliers, in addition to new ones to see what our options were. “Top down” recycling guidance from Government and Council is subject to a separate blog Waste Plastic Products – action by government, suffice to say, agreement as to what constitutes Dry Mixed Recycling from one authority to another is a challenge.

It was apparent that working closely with any recycling partner was going to be key so we actively encouraged suppliers to site so they could get a clear grasp of what material we would be looking to process, especially with regard to the production waste that we knew we didn’t have the ability to re-purpose in-house. Having pulled every conceivable type of material that could ever pass through our hands we went through them all with the chosen supplier outlining what could and couldn’t be recycled.

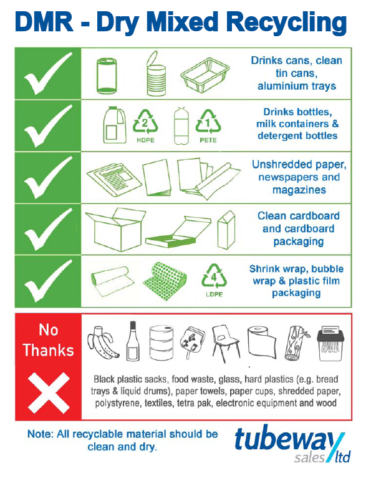

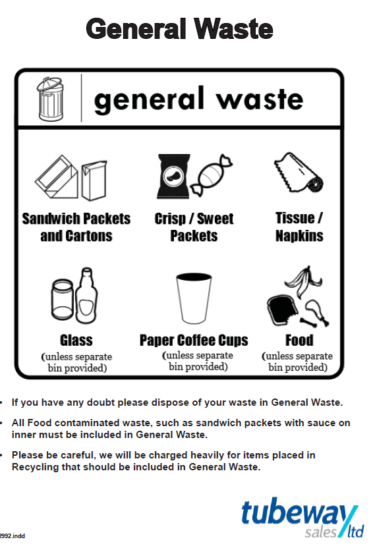

In our observations in researching these articles one of the biggest challenges facing the recycling debate is providing clear examples of what is and isn’t acceptable. We knew one of the biggest obstacles facing our challenge was engaging and bringing our employees on the journey. We wanted to make the transition as smooth and easy for all involved. As a consequence, in collaboration with our recycling partner we produced the following posters that have been placed around the workplace and behind every bin.

As it stands we have completely flipped our approach to waste management. We now have a Skip for Dry Mixed Recycling (DMR) collected on a monthly basis. This is filled from new bins that have been placed round site, with the posters above clearly demonstrating the DMR that is acceptable.

In the early discussions with the recycling partner hesitation was reached on the potential to recycle the manufacturing waste. They agreed to take samples to discuss with their team and compromise was reached that if we separate it from the rest of the DMR they could take and process the production waste. We therefore have 1 tonne bags that separate the Production waste, helping our partner process when the DMR reaches them. Our Production staff take the time to separate the waste we can re-process in-house vs that which will go to our partner for onward recycling.

Lastly, we have an 1100 litre general waste bin that gets collected every 2 weeks. Given this is the waste for an entire manufacturing facility we’re delighted we have reduced it down to this little. That said, we are not resting on our laurels and we plan to address the current material deemed unrecyclable being placed into the general waster for landfill.

I have to say engagement amongst the workforce couldn’t have been better. We’re 6 weeks down the line and rarely do I walk through the factory without someone making comment about the amount we are actually able to recycle, it’s created a real feel good factor that I hadn’t necessarily anticipated.

Further actions we plan to take:

- Our Packing materials: We will continue to look for more eco-friendly alternatives to our current materials. As long as we can ensure the goods reaching our customers remain to the high standard, achieved during 60+ years in business we remain open to changing our working practices. Further exploration is underway to address this.

- Our Suppliers: Can we push our suppliers to source alternative packing materials that are recyclable. Whilst we can’t enforce, we can encourage them to change their packing, sharing the successes we have achieved and hope they follow suit. This may be one issue that is being addressed by a “Top down” governmental approach following the announcement in the 2018 budget of a proposed tax on the manufacturers or importers of plastic packaging. A discussion article including response can be read here: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/819465/Summary_of_responses_to_the_plastic_packaging_tax_consultation_digital.pdf

It will be interesting to see what the results of the proposed tax will be…..

To close off, a nod to the financials. Whilst we’re still in the very early stages it would appear that our changes have more or less worked out cost neutral. We’ve made a slight saving having streamlined suppliers which is offset by a slightly elevated service charge. The fact we’ve had an unexpected boost in staff moral and engagement as a consequence also more than offsets any financial implication. In truth this exercise was never about the money, more an opportunity to lead by example and demonstrate that even those within the Plastic industry take a vested interest in the long term health of our planet.

We’ve come a long way and have further still to go, stay tuned to find out the latest updates……